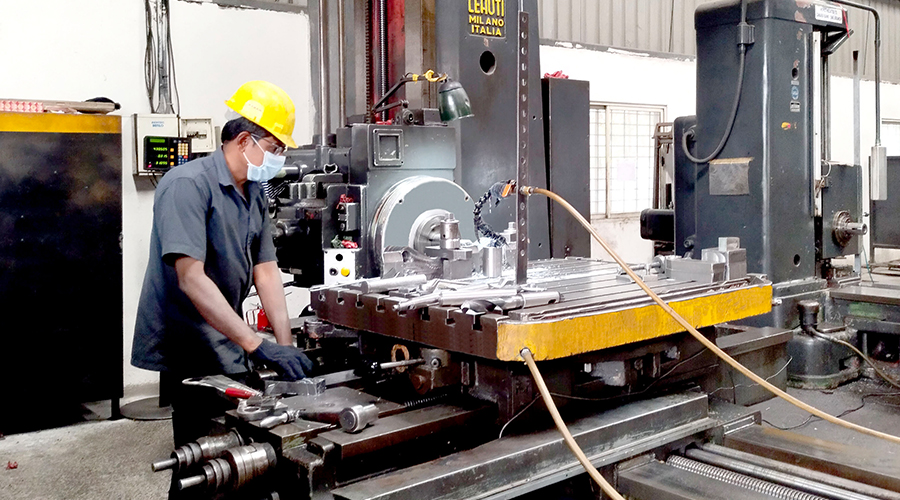

Our Infrastructure

Home >> Our Infrastructure

Providing custom machining services across a wide variety of materials to meet all our customer needs.

We are capable to machine the below materials and alloys with high precision.

Our dedication to excel extends to the last details. We understand that the journey doesn't end with production-it continues into packaging & presentation.

Every meticulously crafted product is carefully nested & thoughtfully placed on euro-type pallets, from steel square box sections. These pallets are a sturdy foundation for our products ensuring safe transport & protection against scratches.